Category: Binsky

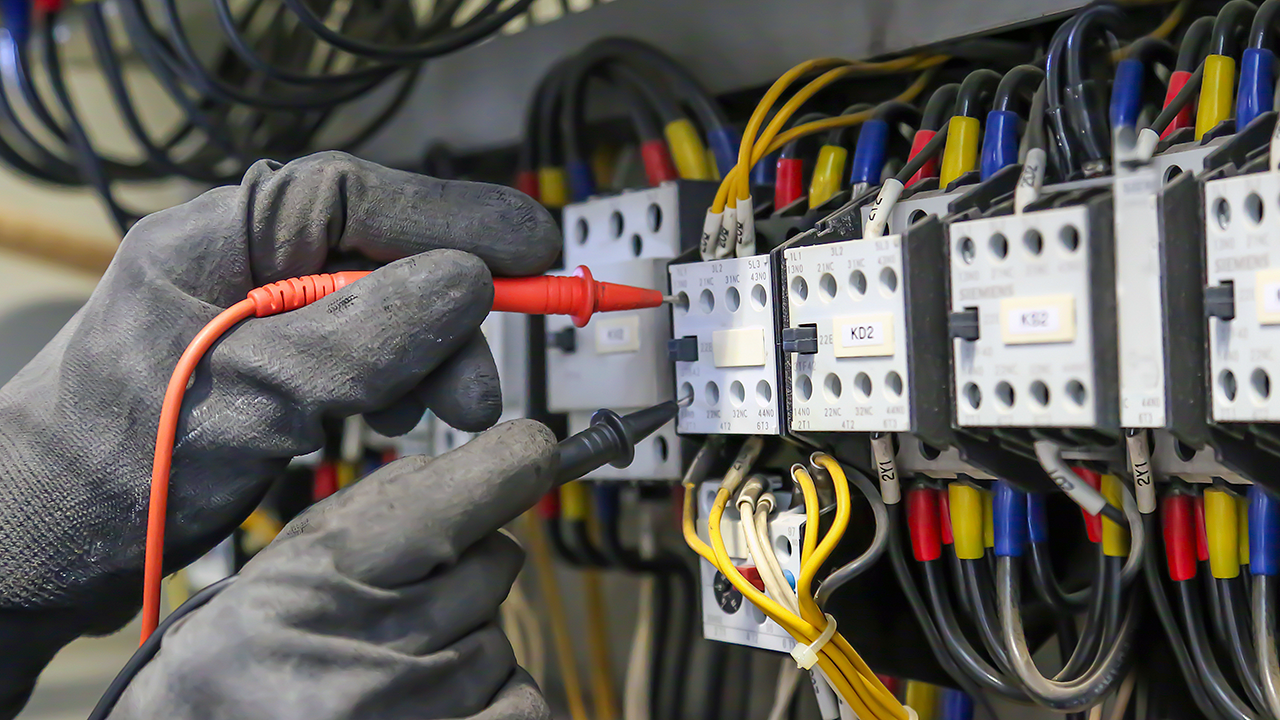

Sufficient Hazards = Stringent Requirements

While the failure of building systems in another industry may result in hours of inconvenience and costly repairs, a similar experience for healthcare facilities can quickly become detrimental to the patients and staff, as well as medical devices or equipment within them. With the ability to prevent exposure to airborne contaminants and stop the spread of any infectious disease in its tracks, efficient HVAC and plumbing systems keep patients healthy and safe.

From surgical suites to pharmaceutical compounding areas, healthcare facilities belong to one of the most highly regulated industries out there. The pressure to meet many industry standards begins in the design phase, carries through installation, and is followed by service and maintenance to ensure factors like pressurization, exhaust, and filtration are measured and maintained. Indoor air quality conditions require routine monitoring, so necessary adjustments can be made. Frequent inspections of air handlers and filtration levels are also recommended to ensure optimal efficiency is sustained.

Healthcare owners that stay well informed regarding these stringent industry standards know that they simply cannot afford to risk hiring anyone other than highly experienced professionals with specific healthcare expertise. Healthcare facilities need mechanical and plumbing systems—and experienced mechanical and plumbing contractors—that they can rely on.

A Reliable Partnership

Selecting a dependable and effective building systems partner means choosing a contractor that stays up to date on industry standards, trends, and news. As an active member of the Healthcare Facilities Management Society of New Jersey, Binsky’s Healthcare Account Manager Darren Siker states, “It’s important to me to stay up to date on the industry—that’s how we can best serve clients’ needs. Our monthly meetings are focused on continuous education.”

Binksy is a design-build mechanical and plumbing contractor that is not only up to date on the healthcare industry, but also familiar with healthcare standards like ANSI/ASHRAE/ASHE Standard 170, Ventilation of Health Care Facilities, and ANSI/ASHRAE Standard 62.1-2010, Section 2.3, covering additional requirements for healthcare in regard to ventilation for acceptable indoor air quality.

We know that following standards from engineering through project turnover directly impact the indoor environment by ensuring proper indoor air quality levels through aspects like appropriate ventilation, humidity, and pressurization. For example, minimum air change rates per hour need to be calculated based on the type and size of the hospital room to achieve acceptable room contamination levels. Relative humidity in operation rooms should not exceed 60 percent if owners intend to mitigate the chance of microbial growth. Likewise, patient isolation rooms that are not properly pressurized with respect to adjacent rooms and areas risk spreading airborne contaminants.

“Our work throughout the pandemic to help healthcare clients manage COVID has focused a lot on ensuring isolation rooms are negatively pressured. We’ve also been adding air scrubbers and servicing HEPA filters,” mentions Siker.

Vital Project Experience

Our team of healthcare facilities experts has planned, installed, and maintained mechanical

systems all throughout New Jersey and Pennsylvania. Binsky’s mechanical services have been applied to everything from preventative maintenance and emergency service to projects designed to upgrade, expand, and construct world-class medical institutions from the ground up. We know what it takes to keep hospitals functional, comfortable, and safe. Healthcare networks trust us to deliver critical projects by executing with the greatest level of care.

Some of Binksy’s recent, large-scale healthcare experience revolved around the “New” Valley Hospital built to serve residents of Northern New Jersey. Providing virtual design and construction expertise for the development of modular components and prefabrication techniques, Binsky not only enhanced the flexibility and operability of the 362-bed healthcare facility, but the overall quality and safety level, as well. By getting involved early on, Binsky was able to collaborate and address many of the facility’s future operations needs at the same time as efficiency goals.

At Hackensack University Medical Center’s new Second Street Pavilion Project, Binsky’s work included the installation of all hydronic and steam HVAC and process utilities and equipment for the podium and tower. Served by a new central utility plant, the pavilion consists of 24 new operating rooms, increasing patient operating area by 50 percent—none of which would be possible without proper indoor air quality.

“Binsky has worked on everything from billion-dollar healthcare expansion projects like Hackensack University Medical Center to small pump replacements or piping repair projects like the maintenance work performed for facilities like Sloane Kettering Memorial Cancer Center,” explains Siker. “Our goal is to be your easy button. Whether you need something large or small, Binksy can do it. And even if you need something that doesn’t align with our services, call us anyway—we have so many industry connections, we can always recommend someone.”

Thinking about the vitality of your healthcare facilities? Eliminate any chance of headaches up front, and contact the reliable, knowledgeable partner you deserve here.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

“Many new construction projects, after turnover and start up, will opt for a preventative maintenance plan, which is good. Internally, we communicate with our other services and divisions. We want to be the easy button to get customers what they need,” states Frank LaCapra, Vice President of Commercial Service at Binsky.

The perks of preventative maintenance help spare owners time, money, and headaches in a variety of ways. Not only does a preventative maintenance contract ensure a proactive approach, it also means owners may easily save thousands (if not more) by avoiding the high costs that come with inoperable equipment. A preventative maintenance plan ensures your systems and equipment operate as intended, extending the overall lifespan, as well as increasing efficiency. For most owners, this leads to lower operating costs, too.

Extended Equipment and Asset Lifespan

Ask any commercial facility operator or building systems professional the best time to budget for equipment repairs or replacement, and you’ll universally hear “right now.” The reason for that is that poor planning often leads to bigger, costlier projects. In many cases, those projects can be avoided entirely through a proactive approach to maintaining building systems, equipment, and the many parts that make up both.

Every system has an average estimated service life, but regular service and maintenance help your systems and equipment last even longer. Activities like changing filters, tightening belts, or cleaning condenser coils can go a long way for the lifespan of your building systems and equipment. Plus, in order for systems to remain under warranty, many HVAC manufacturers require the system to receive regular preventative maintenance.

“Improper maintenance or neglect—for instance, if things are not cleaned—can cause some pretty big issues. The purpose of our work is reassuring every piece of equipment—every asset—has a history associated that we can log in to see and evaluate,” explains LaCapra.

The benefit of Binsky’s commercial service professionals having an ability to review past service for all the parts and pieces that make up important building systems is both familiarity with a facility’s operations and an added level of accountability in the case of certain prescribed maintenance activities. Through regularly scheduled inspections, service and maintenance professionals also ensure HVAC and plumbing systems are operating as designed—and any potential issue is corrected immediately.

Improved Efficiency and Energy Savings

When building systems operate incorrectly, the result is inefficiency. Routine check-ups from maintenance professionals, however, help increase efficiency. By quickly correcting any errors in the ways systems and equipment operate, these scheduled inspections and maintenance activities can lead to substantial energy savings. In fact, clients that implement preventative maintenance plans to ensure their facilities consistently operate at optimal performance have seen decreases of up to 25 percent of total energy usage.

Through a preventive maintenance program, commercial facilities can improve operational efficiency while also achieving an excellent return on investment. The initial investment of a preventative maintenance agreement can come back tenfold through increased energy savings and the preservation of parts and equipment. The larger the size of the facilities and the higher the complexity of the operational requirements, the more a commercial owner stands to gain from such preventive and predictive maintenance tasks that can lower annual energy costs.

“There are situations where you may have a facility engineer—and they can do many things throughout the building—but some things may just be too technical or time-consuming. That’s why they benefit from a preventative maintenance agreement,” states LaCapra. “We have different options, but larger clients mostly select our Facility Management Operating Agreement, employing a stationary local 68 operating engineer to manage the facilities full-time.”

Avoid Emergency Repairs and Interruptions to Critical Operations

With better performance, comes fewer repairs and interruptions to facilities operations. The work performed by commercial service technicians through a preventative maintenance agreement allows parts and equipment to operate better, thereby keeping them in operation longer.

Emergency service calls not only disrupt critical facilities operations and can decrease equipment longevity, but also cost owners extra in lost productivity. Every owner wants well-functioning systems that come without unpleasant surprises and a preventative maintenance plan makes that objective a reality.

Binsky’s standard preventative maintenance agreements include routine maintenance, 24/7 emergency service, priority service calls, preferred labor rates, and necessary materials like filters, belts, or grease. Binsky’s full coverage agreements include everything in the standard agreement, as well as emergency inspection or diagnostics, and the cost of labor, parts, and materials, too, with some exceptions.

“Through a Preventative Maintenance Inspection Manual, we list all equipment covered in the agreement and the schedule of inspections. Then, each time a technician comes on site, the manual is where Binsky’s recommendations and repairs are documented for easy reference,” explains LaCapra.

Don’t risk downtime during peak performance hours! With various plan options and solutions, Binsky will work with you to meet your facility’s unique needs and goals year-round in all seasons.

If you’re ready to increase the lifespan of your building systems & equipment, achieve optimal cost & energy savings, and decrease downtime for your commercial facility, contact our team of expert, reliable technicians at 732-369-0100, or submit a request to get started. For an overview of our Preventative Maintenance Agreement (PMA), click here.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

For Binsky, virtual is much more than a buzzword. Virtual is how we thrive. As part of our effort to remain up to date on industry trends and technologies, we began implementing virtual design for construction activities (including virtual reality headsets to view conceptual models in a virtual space) years ago. Through building information modeling (BIM), we are able to create virtual models of our projects prior to installation, thereby increasing collaboration and accountability across the entire project team. Not only does this process lead to higher efficiencies and decreased requests for information (RFIs) and change orders, it also leads to significant project savings in terms of budget and timeline, safer working environments, and enhanced quality control.

By getting involved from the onset of a project and implementing BIM, Binsky’s design team has the opportunity to make improvements to the design. Our designers create a detailed digital model that mirrors the project to be constructed so precisely that we call these virtual representations ‘digital twins.’ The digital twin is ideally developed in the initial design phases prior to construction, allowing the entire project team to review cost, progression, and construction feasibility upfront.

“We’ll build the model, building exactly as it will be built in virtual form. We used to see 80 percent of a project’s duration allocated to construction, but that time needs to be spent on design now. When it is, installation is able to occur mainly offsite, ahead of schedule, with less labor,” explains Dan Reuter, Vice President of Virtual Construction at Binsky. “By dedicating more time to design and planning, we can ensure accuracy down to every last valve and fitting.”

Opportunities and Advantages for Everyone

One could then surmise that simply avoiding the risk of rework—and the high costs of labor and materials that come with it—prove the case for virtual design, alone. But let’s venture past the elimination of change orders and take a closer look. The type of superior solution developed through unique technology like BIM and other software leads to leaner projects, improved coordination, enhanced quality control, and possibilities for prefabrication and modular construction. Most notably, owners receive:

- Improved timeline and estimate accuracy

- Turnover date certainty

- Risk minimization

- Safer field installation

“Virtual design for construction is truly a game-changer for our installs. We can now have a whole mechanical room delivered on one truck. We can even reduce the footprint of a mechanical room by half if we do it ahead of time. We can take the work out of a job site and bring it to the fab shop. That not only offers safer working conditions for our fitters but helps the project schedule stay on track too,” Reuter states.

When Binsky joins a project team early, our virtual design for construction activities helps ensure the design makes sense for all trades. More than a tool for the planning and execution of design and construction, virtual design software also allows us to test ideas, land on advantageous alternatives, and spot interferences before fabrication begins. These small alterations result in large overall improvements to the fabrication and installation needs of the project, benefiting all trades—not just the mechanical and plumbing subcontractors.

Prefabrication Made Possible with Virtual Design

The assistance of virtual models is extremely useful for Binsky to arrange offsite prefabrication, and in some cases, modularization prior to the install. In our fabrication shops, teams assemble large portions of the design, which enhances quality control and limits safety hazards. Additionally, we can fabricate necessary skids and racks ahead of schedule so that they can be delivered and installed to the job site efficiently, helping to close any labor gaps between trades. As the mechanical scope is typically the most complicated and critical element of a project, Binsky’s prefabrication and modular construction capabilities help in reducing onsite construction time and meeting the project schedule—especially in situations where a traditional approach would lead to delayed timelines.

Binsky’s recent virtual design work for Hackensack Hospital in New Jersey, for example, resulted in a 50 percent reduction of field labor. By shifting those man-hours to the fabrication shop instead, everything normally assembled in the field was manufactured and assembled offsite, allowing for increased quality control, better productivities, and increased safety.

Working on another project, Merck Formulation, Binsky applied the same idea from the basis of design to the schematic design, and all the way up to the construction phase. Using structural multi-trade racks, all plumbing and HVAC equipment was skidded and all piping, valves, specialties, and equipment were bundled and completed ahead of time in Binsky’s fabrication shop.

Better Than BIM: Binsky DFX Live

Smart, data-rich virtual models have created an unmatched opportunity for collaboration and coordination throughout the many phases of a project, particularly installation. Adding time and cost, as well as facilities management, to three-dimensional virtual models allows Binsky to take those benefits a step further.

Binsky is currently developing in-house software which builds upon the digital twins of ongoing projects to allow for a level of productization and standardization similar to that found in the manufacturing industry. Called Binsky DFX Live, the software pulls information found in the virtual model like the number of fittings or linear feet of pipe needed into a live database and applies it to variables like schedules, labor hours, and planning pricing. Binsky DFX Live can help identify labor gaps as well as lead to better coordination and further opportunities for prefabrication. Binsky’s team can then go into the program to check the status of materials, whether the equipment has been coordinated, or scheduled for delivery. Using lessons learned from past projects and expertise from both engineers and in the field, packaging and standardizing becomes possible. Binsky already applies manufacturing and lean principles to the built portion of a project, but this form of industrialized construction means tried and true parts and pieces can become manufacturable.

Taking those benefits into account, it’s no surprise that virtual design for construction is better for the trades and their respective laborers, better for budgets, timelines, and overall efficiencies, and better for an owner’s bottom line. Although it takes a professional to properly implement the virtual design in its most advantageous form, the overall concept is not too different than the old standby of “measure twice, cut once” in its ability to deliver enhanced outcomes from planning ahead and problem-solving.

If your project would benefit from increased offsite prefabrication, decreased onsite field staff, greater quality control, minimizing change orders, and a reduction in potential safety hazards on the job site, the answer is simple. Contact Binsky to experience the benefits of virtual design firsthand.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

Maintaining your building will also require some additional precautions and measures. As you plan for your employees to return, you are most likely considering methods to improve cleanliness and indoor air quality (IAQ). Industry experts such as ASHRAE and BOMA have made several recommendations to ensure better IAQ to help prevent the spread of COVID-19 and other illnesses.

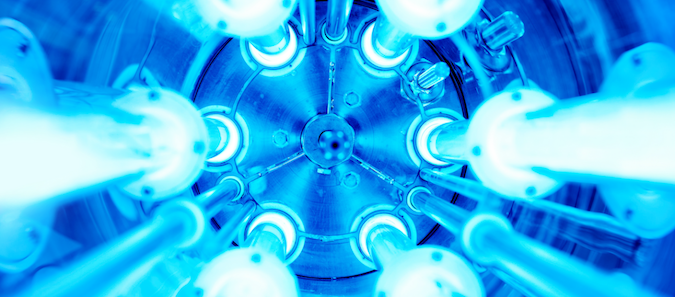

Bipolar ionization and Ultraviolet (UV) lighting for HVAC systems has become one of the most popular and effective solutions for eliminating bacterial and viral microorganisms from mechanical systems.

What is Ultraviolet light and how will it improve my IAQ?

Ultraviolet (UV) light is a form of electromagnetic energy produced naturally by the sun. UV light is split into four distinct spectral areas: UVV, UVC, UVB, and UVA. The entire UV spectrum has long been known for its ability to disinfect and kill bacterial and viral microorganisms. The UVC wavelength has been proven to be most effective, killing more than 90% of dangerous microbes upon exposure. UVC light penetrates the cell wall of organisms and destroys DNA molecules, preventing reproduction.

UVC lamps provide a more powerful and concentrated effect of ultraviolet energy than can be found naturally. For over two decades, UVC technology has been used extensively in HVAC equipment to improve IAQ. These germicidal UVC lamps are installed within air handling units to inactivate microorganisms, disinfect moving airstreams, and eliminate the buildup of contaminants on the surfaces of system components including evaporator coils, drain pans, air filters, etc.

UVC lamps come in a variety of types and sizes which allow them to be inserted into HVAC ducts, typically downstream of the cooling coil for maximum efficiency. These shatter-proof lamps are built to run for approximately 9,000 hours, and require low maintenance, as replacements occur annually.

How does Bipolar Ionization improve IAQ?

Similar to the ultraviolet energy from sunlight, bipolar ionization technology dramatically improves IAQ. Bipolar ionization systems create negatively and positively charged oxygen ions. The negative ions contain an extra electron, whereas positive ions are missing an electron resulting in an unstable condition. To correct this imbalance, the bipolar ions seek out atoms and molecules to trade electrons, which neutralizes particulate matter targeting virus cells, bacteria, odors, and volatile organic compounds (VOCs).

When outdoor air enters your facility, oxygen molecules will flow through a system of bipolar ion tubes which converts them into these positively and negatively charged ions. These ions travel into your occupied space and seek out poor-quality air particles. When these two elements combine, they break down and are eliminated to reduce contaminant levels in your airstream. Essentially, you can imagine the bipolar ionization system as a magnet that is aimed to eliminate harmful particles from the air.

Bipolar ionization systems can be installed in new or existing HVAC systems, including rooftop units, PTACs, ductwork, etc. These systems require very little maintenance, as the tubes should be changed approximately every two years.

Both of these systems will enhance your indoor air quality. Binsky is actively installing these systems for our customers to help ensure a safe return to work. Our team of experts can tailor a solution that fits your budget and overall needs.

Call Binsky at 877-4-BINSKY or visit our website to schedule a free walkthrough of your facility.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.