Category: Binsky

Indoor air quality (IAQ) plays a vital role in human health and overall well-being. We spend a significant amount of time indoors, whether at home, in the office or other workplace, and in other enclosed spaces like education facilities, retail & entertainment venues, and more. Ensuring the air we breathe indoors is clean and safe is essential. One crucial factor in maintaining good IAQ is the proper functioning and maintenance of heating, ventilation, and air conditioning (HVAC) systems. In this post, we will explore the significance of IAQ, the impact of HVAC systems, and practical steps to ensure safe, indoor air quality for occupants of commercial and industrial spaces.

The Importance of Indoor Air Quality

Indoor air quality directly impacts human health, productivity, and overall quality of life. Poor IAQ can lead to a range of health problems like allergies, asthma, respiratory issues, headaches, fatigue, and more severe long-term effects. Factors such as indoor pollutants, inadequate ventilation, and high humidity levels — as well as environmental & climatic conditions (such as wildfire effects) — can contribute to the deterioration of IAQ. Additionally, certain climatic conditions can increase the potential for indoor moisture and mold growth, if not controlled by adequate ventilation and air conditioning.

The Role of HVAC Systems in IAQ

Commercial HVAC systems play a critical role in regulating indoor air quality. They control temperature, humidity, and airflow ensuring a comfortable and clean air environment. Some specific ways in which HVAC systems impact IAQ:

Ventilation:

Proper ventilation is necessary for removing stale air, pollutants, and odors from indoor spaces. HVAC systems use ventilation methods that bring in fresh air from outside and exhaust stale air. Efficient ventilation reduces the concentration of indoor pollutants, maintains oxygen levels, and promotes a healthier indoor environment.

Filtration:

HVAC systems include air filters that trap and remove particulate matter, allergens, dust, and other contaminants from the air. High-quality filters can significantly improve IAQ by reducing airborne particles and allergens, particularly benefiting individuals with allergies or respiratory conditions.

Beyond traditional air filters, modern HVAC systems can incorporate advanced filtration techniques like HEPA filters or UV-C sterilization. These technologies can effectively capture even the tiniest particles – including bacteria and viruses – enhancing IAQ and providing an extra layer of protection for occupants. Select air filters with high Minimum Efficiency Reporting Value (MERV) ratings. Higher MERV ratings indicate better filtration capabilities, capturing smaller particles and allergens. Consult with HVAC experts to determine the most suitable filters for your particular system.

Humidity Control:

Maintaining appropriate humidity levels is crucial to regulate IAQ. Excess moisture can lead to mold growth, while low humidity can create dryness and discomfort. HVAC systems regulate humidity levels, preventing the proliferation of mold, bacteria, and other harmful microorganisms.

Enhancing Indoor Air Quality through HVAC Systems

To optimize IAQ, it’s important to take proactive steps for HVAC system maintenance and operation. Here are some practical tips:

Regular Maintenance:

At the minimum, schedule routine / seasonal maintenance for your facility’s HVAC system, including filter replacements, cleaning of coils & air ducts, and thorough inspections. Regular maintenance ensures that the system operates efficiently and safely, removing pollutants and maintaining optimal IAQ.

Proper Ventilation:

Ensure that your HVAC system provides adequate ventilation for the size of the space. Consider utilizing energy recovery ventilators (ERVs), or heat recovery ventilators (HRVs) to minimize energy loss while ventilating indoor spaces effectively.

Control Humidity:

Monitor and maintain appropriate humidity levels using dehumidifiers or humidifiers, depending on the need. Keeping humidity within the recommended range (usually 30-50%) helps prevent mold growth and promotes a healthier indoor environment.

Intuitive Building Design:

The integration of HVAC systems into the architectural design of buildings can also contribute to improved IAQ. Properly placed air vents and ducts ensure uniform airflow, preventing stagnant pockets of air and enhancing overall air circulation. This design-conscious approach enhances the effectiveness of HVAC systems in maintaining IAQ.

Beyond standard factors that contribute to indoor air quality in commercial and industrial spaces, unexpected or extreme environmental conditions — like wildfires and other events — prove that regular or seasonal maintenance is not enough. Binsky strongly recommends HVAC systems receive additional evaluation and support with filter replacement, coil cleaning, and any other necessary services unique to your system’s equipment.

Binsky’s team of experts are equipped to perform the work required to minimize hazardous risks and potential issues to your cooling system like threats to occupant safety, unnecessary downtime, extra costs, and compromised lifespan of equipment. Fill out the form below to connect with us or visit our HVAC Solutions section for more information.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

Industries at the forefront of research & development and precision manufacturing, such as life sciences, biopharmaceutical, and technology, face many unique challenges throughout their building projects—beginning with the partners chosen to execute Hygienic services and high-purity welding work.

With manufacturing processes that are labor intensive, strictly regulated, and reliant on high quality, hygienic services projects demand both expertise and experience. Requiring more specialized equipment and engineering work, it is essential to partner with an experienced hygienic services contractor with the capabilities, knowledge, and documentation packages for FDA validation requirements that are necessary to meet strict regulations and timelines.

What Exactly Are Hygienic Services?

Hygienic Services are centered on high purity welding. A high purity weld is any weld that contains fewer than ten parts per million (ppm) of contaminants like oxygen, hydrogen, and carbon. High purity welding is used in the semi-conductor, pharmaceutical, healthcare, aerospace, and food & beverage industries, to name a few. This work is performed in a cleanroom setting, in a controlled environment, preventing fewer contaminants from entering the weld area. This is critical because the gases or fluids moving through the tubing and piping need to remain very clean.

Weld quality and integrity is primarily based upon the penetration, oxidation, and bead of the weld. A weld is at its strongest when the bead fully penetrates the inner wall of the tubing or piping. A partially penetrated weld is proven to be inferior in its sustainability.

In the industries previously mentioned requiring high purity systems, oxidation of the weld is another solid indicator of the quality of the work performed. “Unclean” welds, or welds with heavy oxidation, lead to contaminates infiltrating the contents of the system or equipment connected to the tubing. To eliminate this contamination, the welder purges the equipment with an inert gas along its exterior and interior surfaces to help decrease oxidation levels which yield more hygienic welds.

How and Where Does Binsky Perform This Service for Clients?

The use of orbital welding equipment is one of several key factors in Binsky’s ability to manufacture successful, high purity systems for clients. Binsky has been investing heavily in its extensive inventory of orbital welding equipment since 1986. Today, Binsky’s hygienic services team employs expertly trained, qualified ASME IX Certification professionals excelling in orbital welding processes. Click here for Binsky’s Hygienic Services overview.

Orbital welding produces high-quality, high-speed welds for hygienic applications, and allows welding in difficult-to-reach places. The orbital welding process uses an electric arc that moves around the specified work area at a set speed and depth. A bead of metal then forms a perfectly welded seam between two pieces of stainless-steel piping without gaps.

Creating weld joints with flat, smooth surfaces, this service is essential for many life sciences, biopharmaceutical, and technology manufacturing projects. These smooth, flush welds help reduce the risk of corrosion or contamination.

Because the success of high purity projects, specifically in the life science and biopharmaceutical space, depends on its quality, the use of ASME bioprocessing equipment (BPE) compliant components in the creation of hygienic systems is vital—and in some cases, nonnegotiable in terms of adhering to strict industry standards. All orbital welding equipment (like arc machines and weld heads) used by Binsky’s hygienic services team is BPE compliant, ensuring sanitized precision every time.

With a state-of-the-art fabrication facility, Binsky has the capacity to perform high purity work within a safe, controlled environment. Part of Binsky’s facility, as well as specialized tools & equipment, are dedicated to the manufacturing of high purity process systems. By performing such fabrication services offsite in hygienic-only areas, the systems’ chance of encountering cross-contamination decreases immensely.

In addition to increasing safety and cleanliness, offsite fabrication also enables Binsky to work indoors through all types of weather and conditions. More welds can be performed in a similar (or possibly shorter) period of time, leading to higher productivity. Overall, this equates to unmatched quality control and drives the project schedule – whether Binsky is tackling single spool manufacturing or a multi-million-dollar installation.

Documentation – A Critical Requirement for FDA Validation

Once high-purity systems have been transported to the project site for system installation, passivation, and testing, Binsky delivers a comprehensive documentation package that is designed with a smooth turnover in mind for clients to meet the FDA’s validation requirements. Knowing our weld documentation packages are a vital part of the validation and turnover process many manufacturers must undergo before receiving FDA approval, they are designed to be as thorough as possible.

Our Commitment to Delivering Comprehensive Documentation

The FDA requires documentation of the weld process and materials used to manufacture a welded component. These documentation packages detail all this information, which you must submit with the application for clearance. The thoroughness and clarity of a weld documentation package will significantly influence whether your product receives clearance from the FDA. Although this seems complex and tedious, Binsky has already done the heavy lifting for its clients throughout project stages. Furthermore, specific parts of the validation process, such as IQ (Installation Quality), OQ (Operational Quality), and PQ (Performance Quality) are given the same thoroughness as other components of documentation packages prepared for FDA requirements. Binsky is experienced in and involved with these stages of the process, ensuring full support to our clients.

Each of our welds can be systematically identified by system, ISO number, and weld number in our weld documentation package – along with the date the weld was performed and the welder’s name and qualifications. And to prove Binsky’s ultimate accountability, we will encourage a client to choose any weld on a project to locate the corresponding weld detail and put our comprehensive documentation package to the test. This is another area where our decades of hygienic services experience shines through, providing clients the critical information needed for documentation turnover, and FDA validation for proof of regulatory compliance. Additional to making our clients’ jobs easier, Binsky’s weld documentation package ultimately helps clients increase the speed at which their products hit the market.

The Bottom Line

Binsky’s hygienic services team delivers the end-to-end support needed to maximize the potential of your high purity project. Browse the many hygienic services projects featured in our project gallery, or contact us today to discuss how we can partner with you on your next project.

For decades, Binsky has supported facilities and their owners in a variety of ways—but for most, quality and speed to market is bar none. Binsky offers a wide range of end-to-end hygienic services, from engineering to fabrication to installation to preventative maintenance.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

Commercial building con

Fortunately, a mechanical, electrical, and plumbing (MEP) contractor can help foster collaboration, increase quality, and streamline solutions. Partnering with a full-service MEP provider, such as Binsky, can potentially save owners both time and costs.

Two of the most talked about trades are the “M” (mechanical) and the “E” (electrical)—likely, because they both play an important role on any commercial project team.

Levels of collaboration between the mechanical and electrical teams can often make or break a project. With a strong partnership between these trades, everyone wins. However, without tools like proactive communication and clash detection software, it becomes much more difficult to hit milestones along the project schedule and deliver a quality end result.

To learn a little bit more about how these two trades can combine forces and execute their best work, let’s look at the responsibilities of each:

Mechanical Scope of Work

As the party responsible for the heating and cooling systems, refrigeration, piping, and plumbing of a building, the mechanical scope of work can include the installation of:

- Fire and smoke protection features and systems

- Interior environment (HVAC)

- Plumbing lines and fixtures

- Elevators, lifts, etc.

- Interior and exterior structured design members

- Accessibility features

- Rooftop assemblies and structures

- Energy efficiency components

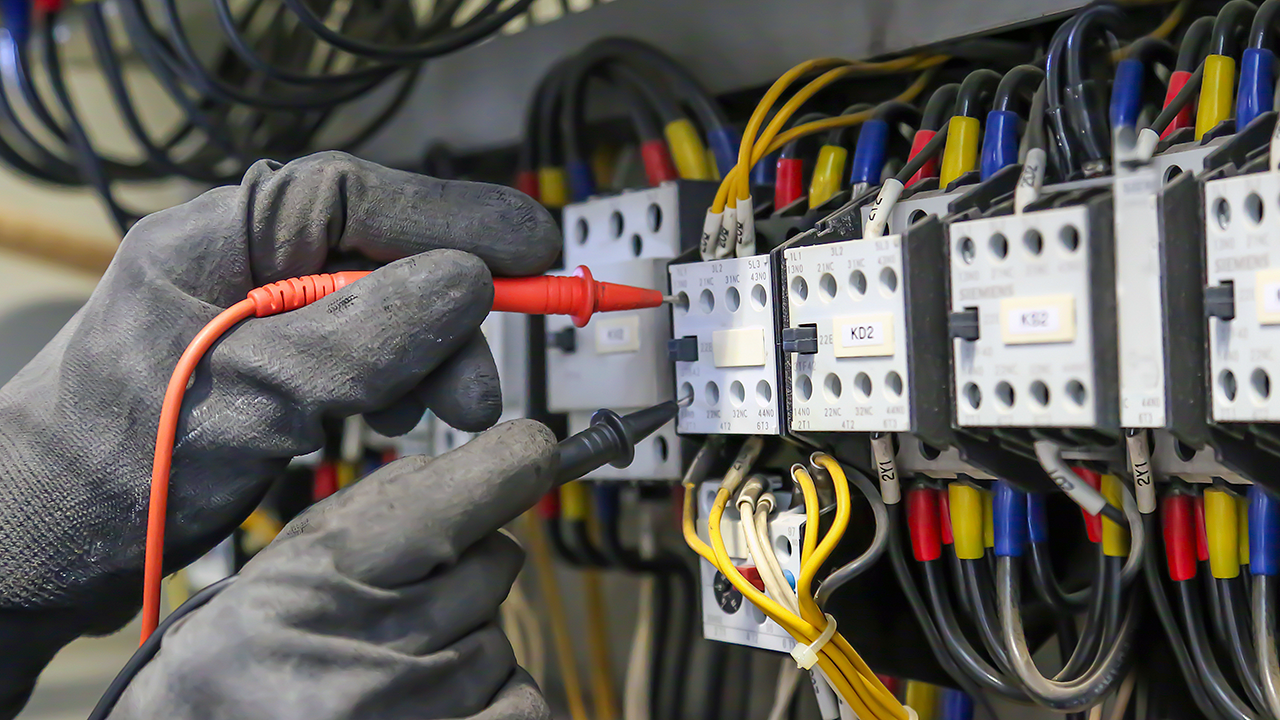

Electrical Scope of Work

Accountable for the design and installation of electrical wiring and conductors used for light, heat or power, the electrical team of a commercial building project also have a complex task at hand. They are typically responsible for the installation of:

- Conduit

- Wiring pulled through the conduit

- Address every electrical requirement over every square inch of the building

- Power panel distribution and termination according to the SOW (Scope of Work)

How Electrical Services Tie into Mechanical Work

Perhaps the most underrated tool in the electrical team’s tool belt is their ability to collaborate with the mechanical team for spot-on installation of all electrical components of the building.

An electrical team’s job might mean ensuring a quarter mile run of conduit ends precisely where the mechanical contractor will need that power for installing HVAC elements like commercial air handlers. Factor in the potential for extreme working conditions, such as 40-feet high ceilings for an electrical crane bay, and collaboration becomes essential.

Mechanical contractors with a strong desire to do great work understand the importance of this collaborative approach. Binsky knows that successful collaborative efforts between the electrical and mechanical teams pays off. When mechanical and electrical efforts have been fruitful, those efforts will manifest themselves in the form of being on time and under budget!

The Key to Contractor Collaboration

The ultimate goal of every client or building owner undergoing a commercial building project is to get the job done as quickly and efficiently as possible. The way to achieve that goal is by open, continual collaboration of the mechanical and electrical teams.

Keeping the collaboration between mechanical and electrical teams flowing during the construction process begins on day one. Both contractors should have a liberal open-door policy with each other throughout the building process and both should include healthy collaboration as an integral component of the scope of work to be done.

One way to achieve these goals is to implement Building Information Modeling (BIM) software as an effective collaboration tool that both mechanical and electrical teams could benefit from. Through the use of clash detection and ensuring both partners’ designs can be implemented seamlessly during the installation, time and money is often saved.

Fostering these collaborative efforts and making the most use of them could be the difference in this job being the last one for that owner or becoming that owner’s mechanical and electrical team of choice.

When commercial building projects begin with comprehensive collaboration and continue that collaboration throughout each party’s scope of work the results are better accountability, shortened project schedules, and lower overall costs from doing things right the first time.

A trusted MEP partner like Binsky delivers more than high quality, seamless MEP solutions. With Binsky, owners also receive the ultimate peace of mind, knowing their commercial building was built collaboratively with the end user in mind.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

As in most building systems, the plumbing needs or potential problems related to the plumbing systems in commercial buildings can result in quite complicated scenarios requiring complex solutions. These complex solutions can include activities like backflow prevention, video scoping, hot water jetting, and more. Together, these processes and solutions fall under the umbrella of specialty plumbing services.

A reliable MEP provider serving commercial HVAC, electrical and plumbing systems, such as Binsky, knows how to determine which of these solutions your commercial building needs for uninterrupted operations. With a client portfolio made up of leaders in pharmaceutical, healthcare and higher education, Binsky’s experienced team of plumbing experts is well versed in helping building owners and operators identify what’s needed when to prevent downtime and unnecessary expenses.

Let’s take a closer look at the specialty plumbing services certain commercial facilities require to help you plan for success and stay ahead of your building’s needs:

Backflow Prevention

Situations like pressure changes within water pipes or a break in the water line can cause a backflow of water in your plumbing systems, not to mention some very unsanitary conditions. Backflow water can bring many contaminates, including waste, pesticides, and other chemicals with it.

Like the name states, backflow preventers allow water to flow through pipes in the desired direction only by preventing water from flowing the opposite way. Backflow prevention is so important, in fact, that the National Plumbing Code has become more and more focused on the installation and maintenance of backflow preventers in industrial or commercial plumbing in recent years.

At Binsky, our specialty plumbing team is knowledgeable about the current requirements for backflow prevention and how it pertains to your building. From recommending the proper backflow preventer to installation and maintenance, we can help you understand these requirements and prevent backflow from affecting your facilities.

Video Scoping

Sometimes, plumbing problems occur where you cannot see them. A variety of issues can arise from unidentified blockage or even pipe breakage. Unfortunately, it is often the problematic symptoms of these root causes that show up first. The root cause, however, is typically not visible to the untrained eye. This is precisely why it’s important to engage an experienced professional with video scoping capabilities.

Despite not being able to view the root cause of plumbing pipe issues firsthand, a professional is able to make an educated guess about what the problem may be and then confirm with video scoping. By fishing a specialized camera and equipment through the pipe, professionals are able to visually inspect what is going on inside like obstructed piping or pipe in need of repair. This integral specialty plumbing service can help quickly locate—and solve—a problem, ultimately saving building owners both time and money.

Hot Water Jetting

If a portion of a pipe or plumbing system has already been identified as obstructed, hot water jetting may be a viable solution. Using high-pressure hot water to blast through clogged pipes, hot water jetting can also break down certain substances lodged in your facility’s piping.

Well known in the restaurant, automotive, and healthcare industries, hot water jetting is paramount in commercial facilities needing to rid drain lines of harmful contaminants. Hot water jetting has proven useful in liquefying clogged waste, killing bacteria, and preventing a clog from being washed down further in the line. This solution is often faster and more efficient than other methods, too.

Preventative Maintenance

Last but not least, taking a proactive approach to your commercial building’s maintenance is always a good idea. With a comprehensive preventative maintenance program, building owners and operators can stay on top of the health of the facility by adhering to a predefined preventative maintenance schedule.

A good preventative maintenance program helps identify any specialty plumbing needs early on, thereby saving building owners from experiencing a loss in uptime that negatively affects building occupants and operations. Another plus of preventative maintenance is that it has become a key selling point in attracting and maintaining quality tenants for commercial rental spaces because, giving potential tenants peace of mind that any potential issues will be proactively addressed.

From backflow prevention and video scoping to hot water jetting and preventative maintenance, Binsky knows what it takes to take on the specialty plumbing needs of your commercial facilities. Our expertise focuses on your building systems so that you can continue to concentrate on the work you do best. As the world begins to get back to business in a post-pandemic society, Binsky is ready to provide answers to your questions and solutions to your problems. Contact us today to determine how we can assist with your commercial building specialty plumbing needs.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

Call it a building management system, building automation, or simply controls. Known by a few different names, a building management system (BMS) adapts indoor ecosystems to create energy-efficient environments. Used for everything from occupant comfort to reducing operational hours and reducing loads, a BMS solution can go a long way in helping building owners conserve energy and resources. Sometimes combined with other systems such as lighting, the BMS helps many aspects within a given facility in order to optimize overall performance and ensure uptime for building owners and occupants.

Binsky offers this service, knowing a BMS helps to control and regulate the essential building systems and equipment that allow a facility to operate as it needs to on a daily basis.

“Building management systems can be used to control just about anything. From chillers and boilers to AHUs and VAVs,” explains Justin Woodruff, Field Supervisor and Controls Manager at Binsky.

For example, some basic BMS functionalities can include:

- Boiler management

- HVAC management

- Auto control and scheduling of system operations

- Control and monitoring of core mechanical and electrical equipment

- Adjustment of ventilation

- Handling of smoke and alarm systems

- Checking plumbing and water systems

Controlling indoor conditions such as humidity, temperature, pressure, and more, a BMS involves both a frontend and backend system. Using a blend of software and hardware, building management systems are fully customizable solutions that utilize sensors and make the best use of the Internet of Things (IoT).

Each system is built on control panels wired into the structure’s valves, sensors, and switches. Sensors can monitor temperatures and humidity with the capacity to create zones depending on needs, such as a refrigeration unit or laboratory requiring a unique climate.

Using Tridium’s open-platform software, Binsky has the ability to integrate to various existing systems. The software has the unique ability to pull points in to read the performance as compared to set parameters.

“Each piece of equipment has points that can be pulled out and linked to the JACE,” Woodruff mentions. “The frontend or “brain,” called a JACE, is where all the points come back to report real-time data from the systems and equipment monitored by the BMS.”

Virtual graphics on the frontend offer a visual snapshot of how everything is working. For example, when heating or cooling coils are operating, one will often see blue for cooling and red on the other coil to virtually show heating.

Meanwhile, the backend of the system is programmed using technical logic to ensure all levels are set to function properly and are adjusted as needed, like setting a system to switch over to mechanical cooling at a given temperature.

“Alarm portals related to the set parameters chosen for the facility’s room temperature or pressure are selected. For example, the BMS can be set up for continuous monitoring of compressors,” Woodruff states.

If the space’s conditions go outside the given parameters for any reason, the alarm is triggered and delivered to the user set to monitor it. Whether that’s an onsite technician or someone else, Binsky is usually contacted to address the issue immediately and determine what exactly set off the alarm. In some cases, the cause may be that the equipment is not actually running, and someone needs to come to look at it.

Once set up on-site, Binsky ensures remote access to BMS capabilities. End users, such as an onsite technician or facility manager, can log in via phone, tablet, or computer. This allows Binsky to view the whole system remotely to help guide customers through it or determine if an on-site technician visit is required.

With the BMS allowing centralized management of the infrastructure, facility managers and owners can rest assured operations are secure, safe, and efficient.

Capable of gathering and storing historical data for examination and trend analysis, the BMS also helps facilitate smart decisions regarding operations and maintenance. Catching and recording any building system or equipment errors through the BMS means engineers and management can quicken response time.

A BMS can help with preventative maintenance too, ensuring any work is completed prior to potential equipment failure. By preventing downtime and service interruptions, emergency service costs are also spared.

Overall, Binsky’s BMS work has proven essential to a variety of industries, especially facilities that simply cannot afford lost time, productivity, or safety concerns. Binsky’s solutions in mission-critical facilities, in particular, have helped customers to avoid unexpected downtime to essential operations. No matter what industry your facilities are focused on, Binsky is here to help. Contact us to learn more about our indispensable BMS solutions or get started on tailormade options for your facilities.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

When commercial business owners and facility engineers consider the many building issues that may lead to sick occupants, it’s likely mold and other indoor allergens

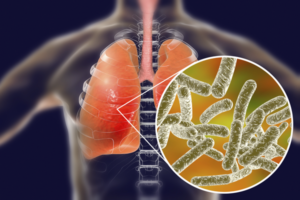

First identified in 1977, Legionnaires is a form of pneumonia made up of bacteria called Legionella. The disease’s name comes from its origin at an American Legion convention, which resulted in 180 attendees falling ill and 29 deaths.

Formed when bacteria enter the lungs either by breathing in very small droplets of water or when water accidentally gets into the lungs while drinking, Legionnaire’s Disease produces flu-like symptoms. Headaches, muscle pain, chills, fever, and fatigue can occur between two to ten days from exposure to Legionella bacteria—especially in immunocompromised populations. Although most healthy people do not get sick when exposed to Legionella bacteria, the best cure is prevention, as complications of the disease can lead to lung failure.

Locating Legionella

Legionella tends to thrive in areas such as hot water tanks, cooling towers, plumbing systems, and even condensation from air conditioning units in addition to the obvious settings of fountains, pools, and hot tubs. Since water is where these bacteria live and thrive, water is where it will appear in commercial buildings.

Certain changes like building construction, water temperature fluctuation, water pressure changes, and antiquated equipment can all make Legionella more of a risk.

Hot water systems that store water and supply a commercial building’s functions can serve as a potential Legionella bacteria breeding ground. If the water in the water heater is maintained at a temperature of below 140° F and the water heater contains scale and sediment, this is a potential problem.

Likewise, cold water systems such as ice machines, grocery store produce misters, and dental water lines can be at risk for disease exposure. Even though these systems store water below 68° F, a temperature in which Legionella does not thrive, the environment around the water system could contribute to bacteria growth. For example, if an ice machine’s water lines are exposed to heat, say, from a condenser coil, this can foster bacteria growth.

Meanwhile, a commercial HVAC system may be a potential contamination source all throughout the building. Pipes leaking into air ducts can be a source of bacteria contamination, whereby the bacteria can spread through the air handling system.

In fact, any systems that use humidifiers and evaporative air coolers also have a potential risk factor if not well-maintained. Namely, coil and heat exchanger leaks and stagnant sump water are something to look at when mitigating Legionnaires’ Disease exposure.

Proper Prevention

Starting in the preconstruction phase, the thought given to the design of the plumbing, water, and air conditioning systems in commercial buildings is crucial. Legionnaires is much less of a risk if your facility’s design-build team efficiently conceptualizes and constructs a hygienic system.

Beyond design and construction, preventative maintenance is one of the best ways to keep Legionnaires at bay, as neglecting your water sourcing and plumbing systems can lead to a facility-wide outbreak. To ensure water source cleanliness and prevent stagnation, start with a water management plan that meets ANSI/ASHRAE Standards.

Binsky’s commercial team and plumbing experts always keep in mind that the design can help prevent the growth of bacteria and ensure easy maintenance and water management.

For hot and cold water systems, recirculating water and getting rid of tanks or capped plumbing pipes that allow water stagnation goes a long way, as does insulating lines to avoid temperature changes from other water lines or equipment.

Since the major source for Legionnaires in HVAC systems is water leakage, we check and properly maintain equipment, such as pipes, coils, and heat exchangers to ensure bacteria cannot grow. Checking and properly maintaining humidifiers, as well as cleaning evaporative air coolers before use helps. It is also key to ensure sump water remains at a cool temperature and never becomes stagnant.

As the maintenance plan is carried out, have your water tested for bacteria. If bacteria is in fact found, water can be treated and disinfected with copper-silver ionization or mono-chloramine to kill it off.

By installing advanced hygienic systems, executing timely preventative maintenance activities, you can avoid Legionnaire’s Disease in your commercial facility. Binsky can offer turnkey solutions to avoid Legionella. Stay up to date with your industry’s best standards and guidelines by partnering with Binsky for your facility needs.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

Circulating the minimum amount of refrigerant in each individual zone, this innovative technology eliminates energy waste while increasing indoor comfort. A VRF system consists of one outdoor unit that feeds multiple indoor units, allowing for individual room controls. These systems operate in “cruise control”, never turning off, thus, never wasting energy from a shutdown or start-up. Predominantly used in Japan, China, and Europe, VRF systems are now gaining traction in the United States due to their efficient operation and quick ROI.

It is important to use an experienced contractor when designing and installing VRF systems for your facility. Install technicians can obtain factory training and certification from manufacturers including Mitsubishi, LG, Daiikin, and Fujitsu. When installed by certified technicians, a ten-year warranty is available on the parts and equipment. These technicians work very closely with the manufacturer during the install, commissioning the equipment, and guaranteeing the most efficient design.

Aside from cost and energy savings, another benefit of VRF systems is the ability to use zoom lock fitting technology. This is a pipe fitting method that does not require brazing or torching. Traditional methods of pipefitting require a burn permit while deactivating smoke detectors in the facility. The zoom lock technology in VRF systems eliminates these tedious steps in the early installation process. Depending on the system requirements, the zoom lock technology may offer you additional cost savings.

If you are considering a VRF system for your commercial or industrial space, contact Binsky to discuss your options. One of our certified technicians will perform a walk-through of your building and make recommendations that best suit your needs.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

Faster, better, safer. Those three words sum up the process of modular construction for design-build mechanical and plumbing contractors like Binsky. Plus, they add up to significant client savings, too.

Modularization, quite simply, refers to something that is designed or produced in separate sections in order to combine as a whole and create the desired end goal. Therefore, modular construction relies heavily on the prefabrication of different parts and pieces, or modules, to be delivered onto a job site to complete the overall building installation.

Binksy’s Project Executive Bob Durr who oversees the company’s manufacturing facilities explains it like this, “Prefab is when the field looks to see how much work can be done in the shop that’s practical. We’ll weld an elbow to a length of pipe or make some Ts and a branch—something that will fit on the back of a truck pretty easily.”

By going a step further to get everything on a skid, we enter into the realm of advanced fabrication or modularization. “If you have a series of hot water boilers and expansion tanks, for example, you make a skid and mount them all in the shop—in a controlled environment, a safe environment,” mentions Durr. “There are no weather conditions to deal with or job site issues you usually run into. The skid is sent out as one piece to the field, so the field is putting in four anchor bolts or so to mount it, as opposed to stick building it in the field,” he continues.

The ultimate type of modularization occurs once coordination with other trades comes into play, garnering results like multi-trade racks. “Control panels with all the equipment pre-wired, racks of piping going out with ductwork and electrical on it, bathroom pods that are already pre-made—that’s the ultimate. And at Binsky, we’ll cooperate with any partner necessary to make that happen,” suggests Durr.

#1: Faster Project Delivery

Through advanced fabrication and modular construction capabilities, Binsky can accelerate speed to market by meeting milestones on, or even ahead, of the overall project schedule. With two fully equipped fabrication shops, state-of-the-art technology, and a dedicated team of mechanical and civil engineers, Binsky is equipped to prefabricate pipe racks, multi-trade racks, equipment skids, sheet metal, plumbing fixtures, and more.

Durr states, “Our project managers are now looking at each job from a much more critical angle as they try to set up prefab or hanger installation packages from the beginning with modules and determine how some of the project’s needs can be met in a modular way.”

Within the indoor environment of a fabrication shop, installation experts can continue to meet project goals regardless of the weather, or work being executed by other trades.

#2: Better Quality Assurance

Another benefit of a controlled working environment is consistent quality assurance. While Binsky always strives to deliver work of the highest caliber, the in-depth planning that goes into prefabrication and modularization efforts ensures the work is done right the first time.

Binsky’s team of design experts uses cutting-edge technology to produce layouts that help determine modularization viability and capitalize on fabrication opportunities. Through software like Autodesk

Revit and virtual reality, our engineers can send fabrication releases to the shops for construction, making for a more collaborative design phase.

In fact, the assistance of virtual models has become so pivotal in the development of Binsky’s offsite prefabrication efforts that it’s led to the creation of Binsky DFX Live, a software program that can obtain the information found in the virtual model.

#3: Safer Working Environments

Working within a controlled environment, like a Binksy fabrication shop, allows for the safer execution of project work, too. Many of the harms and hazards associated with a traditional job site are eliminated with prefabrication or modularization within a fabrication shop.

From production to installation and site work, traditional safety hazards decrease significantly when fabrication occurs offsite. Modular construction, on average, decreases onsite labor by 30 to 50 percent. Fewer contractors working in parallel with one another, fewer laborers on-site, and fewer deliveries all help to reduce site disruption as well as major risks like falls, which account for nearly 33 percent of job site fatalities.

In addition, offsite modularization also helps Binsky’s hygienics division meet the stringent requirements of certain projects involving FDA-validated systems, such as those in the food and pharmaceutical industries.

#4: Cost Savings for Owners

Ultimately, a faster, better, safer job executed with prefabrication and modularization techniques results in cost savings for owners. When owners can rest assured that they will receive exactly what they want when they want it through these processes, it makes one wonder how construction projects were ever executed any other way.

“Recently, we started offering this as a service to clients because of the huge benefit they stand to receive,” mentions Durr. “The benefit for the client is a lower-priced project in the long-run, better quality, and at a faster pace due to less coordination issues in the field.”

“Right now, there are about three or four hospitals we’re doing and some pharmaceutical facilities. The two big ones are Valley Hospital and Hackensack Hospital—both of which involve prefab racks,” state Durr.

“We’re doing as much prefab as we can on our current jobs. We’re doing a lot of rack piping. We try to do everything on these prefabricated racks, send them out with all the different systems—refrigerant systems, hot water, cold water, domestic water, anything you’d usually find. In hospitals, there’s also medical gas. And we’re doing one design-assist project in Pennsylvania that’s requiring a process system for making dog food.”

From hospitals to bio-life sciences to manufacturing, there does not seem to be an industry that cannot benefit from modular construction techniques. As contractors like Binsky continue to pave this path of innovation, everyone involved stands to benefit.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

Furthermore, without a trusted expert to help guide you through preventative maintenance and parts and equipment evaluation, it’s easy to enter a confusing grey area filled with too many options and not enough direction. For example, commercial boilers of the steam and hot water variety can last 30 years or more with proper water treatment, operation, and maintenance.

Why replace it when it can be repaired? Why repair it if it’s just going to need to be replaced next time?

A preventative maintenance partner like Binsky can help commercial owners answer these questions through assessment of their facilities’ complex building systems, like boilers. Through aspects like preventative maintenance history and tasks, lifetime parts replacement history, water treatment reports, metallurgy reports, and regulatory agency reports, an expert can analyze cost versus benefit and determine the best solution.

A commercial facility’s heating system works hard—and sometimes year-round if the building is located in a colder climate zone. Typically, that means all parts are subject to repair or replacement in due time.

Depending on the age of your facilities and building systems, wear, tear, and eventual failure is inevitable, but lack of proper water treatment, deferred maintenance or repair, and lack of professional operation can speed up that process.

In a commercial setting, you simply can’t afford for critical systems like HVAC and plumbing to break down. The idea of boiler replacement may sound expensive to some, but the effects of downtime and potential facility damage far exceed any parts or equipment costs.

Prioritizing your building’s maintenance is essential for your safety, security, and bottom line. But, even a well-maintained boiler system may encounter problems based on the very nature of its operation. When comparing the system’s lifetime data collection costs related to operation and maintenance against the commercial industry’s average costs, a property manager may opt to proactively replace a boiler due to energy savings considerations.

Although a commercial boiler system has a projected lifespan of a few decades, it’s safe to assume most will start experiencing service issues around the ten-year mark. The occasional repair is to be expected and is relatively cost-efficient, but what happens when the need for repairs starts to accelerate? The question is a complicated one, but the following three factors can help you determine when the time is right to replace versus repair:

- Age of the boiler system: If the boiler is approaching the end of its useful life, it may be time to replace it to ensure you don’t wind up with unexpected interruptions to your facility’s operations.

- Time intervals between repairs: Analyzing how often repairs are occurring can help you assess their efficacy. If you experience a steady uptick in the frequency of repairs needed, it may be time to replace the unit altogether.

- Facilities energy costs: Have the energy costs of your commercial facilities increased over time? Is your bill starting to look unreasonable? If your expenditures related to natural gas, oil or electric seem off, there’s a good chance it’s time to replace your commercial boiler.

While boiler system repairs often average a few hundred dollars, the cost of replacement can add up to several thousand. It’s easy to see why some owners are hesitant to replace the entire system, preferring a string of frequent repairs instead. But what happens if the telltale signs to install a new commercial boiler at the appropriate time are ignored?

Whether your building houses businesses and industries or functions as a large-scale apartment complex, a boiler failure means no heat and unhappy tenants. In colder climates, boiler downtime can even cause damage to pipes and other building infrastructure—especially if the components of the boiler room were installed a long time ago under requirements of decades past. Anything from lack of clearance around the actual unit to load changes to insulation alterations since it was designed many decades ago, can result in a dangerous, if not faulty, boiler operation. Given the nature of a commercial boiler, a worst-case scenario may involve extreme damage to the property from the heat and pressure utilized by the boiler.

Knowing when to call in an expert will not only spare you such headaches but will ultimately help protect your budget and building, too. If your facilities begin to experience loss in efficiency, frequent repairs, or loud and unexpected noises from the system, your commercial boiler has likely reached the limits of its useful age. It may be time to consider replacement rather than additional repairs. Plus, replacement also serves as a prime opportunity to make sure any pipes, ductwork, or additional infrastructure is in proper working order.

Partnering with a preventative maintenance contractor like Binsky can help you prevent downtime and disasters caused by boiler deterioration from ever occurring. Having seamlessly provided boiler repair and replacement services to New Jersey and Eastern Pennsylvania for more than 25 years, we specialize in commercial settings and have a team of field engineers ready to help choose the solution that’s best for you.

Repair or replace? Only a trusted professional can determine that for sure. For the reliable expertise of the trusted partner you deserve, contact us today.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

1. Experience

When choosing a mechanical subcontractor for your project, their experience is a substantial determining factor. Aside from the obvious tasks including temperature control and maintenance of equipment, an experienced mechanical contractor will focus on functional installation, cost, and energy efficiency. Their goal should not only be to provide a smooth and excellent installation, rather assess your individual needs and assist you in the design of your mechanical systems. Additionally, a company with many years of experience can work on all HVAC systems regardless of manufacturer or brand. An established contractor will possess long-lasting client relationships, allowing for references to solidify their ability to complete your project.

2. Safety

The construction industry is associated with some of the most dangerous working environments. A subcontractor’s safety program should be of the highest priority for all stakeholders. It is a vital component to completing your project on time and budget, as accidents on the job site will drive up the overall cost of your project, and investigations could potentially delay work. A solid safety program protects workers, as well as the public, from injury. Ask your prospective subcontractor about their program. What actions are taken to ensure a safe job site? Is safety part of their culture? This information will be a key factor in your decision-making.

3. Can the contractor deliver within your budget and schedule?

There is no denying that budget and schedule are two of the most important factors when planning a construction project. Request a detailed estimate and schedule to ensure it aligns with your project needs. A reliable contractor should have the capabilities to overcome a setback and still deliver your project within your financial and scheduling constraints. Always remember, it is important not to compromise the quality of work while planning the scope of the project. The lowest-priced contractor may not always have the highest standards.

4. Staying up to date with industry standards

Mechanical contractors that stay current in construction technology trends are at a much greater advantage when working on large projects. Newer, more efficient tools and software will reduce project time, material waste, and safety hazards. Many of the recent construction trends focus on environmental impact. Staying up to date with industry standards guarantees the highest quality of work with the most efficient results. Be sure to ask questions about how the company stays current in their industry.

5. Setting expectations with strong communication

Take note of how responsive a contractor is when addressing your initial requests. Construction projects often require meetings to address issues, change orders, and timelines. Poor communication will result in project delays. A great contractor will establish a strong line of communication with their clients, setting high expectations for project success. Does the team take the time to explain the construction process? Do they answer your questions thoroughly and offer follow-up information? These are important things to consider when looking for an innovative mechanical subcontractor.

When planning your next construction project, keep in mind: mechanical systems require some of the most creative and complex preparation. Choosing the right mechanical subcontractor can make or break your bottom line. Partner with Binsky to experience the highest level of quality, service, and expertise. Contact our experts for a free consultation at 877-4-BINSKY.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.