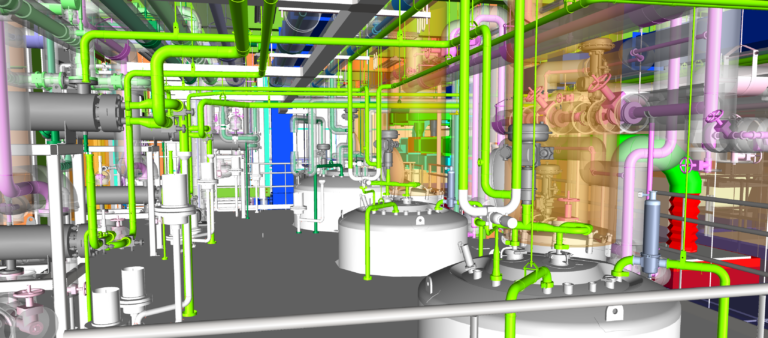

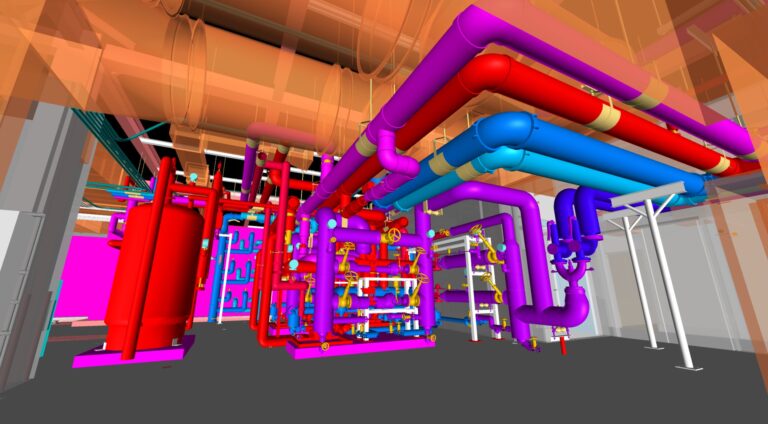

High-Purity Process Piping for Manufacturing Systems

As part of process piping and high-purity, manufacturing systems for Pharmaceutical and Healthcare industries, we at Binsky understand that adjacent components of your project like documentation packaging for critical FDA validation to ultimately foster your product’s speed to market is equally important to the superior quality and sanitation of each weld.

Not only does our Hygienic Services team possess a true comprehension of and ability to navigate and complete these vital project phases, but has demonstrated proven outcomes and innovative solutions for our Life Sciences clients and partners for over three decades.

Ready to Start Your Project?

Turn to a trusted leader in mechanical contracting and construction. Get in touch to discuss your project or request a quote today.